RichiMachine

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

Advantagesoffloatingfishfeedpelletmachine

~6.5 mins read

1. Characteristics of aquatic feed

There are also multiple setups. Drifting fish feed pellet device can refine numerous marine feeds, such as ornamental fish feed, aquaculture fish feed, and so on. According to the nature of fish feed products, it is separated right into sinking fish feed as well as drifting fish feed; it is an suitable equipment choice for the tank farming sector.

Floating fish feed making maker does not require central heating boilers, occupies a tiny area, and is easy to operate. It is a step-type fish feed assembly line with different yields, rate, the day-to-day result is 1-5 tons, which fulfills the manufacturing demand of 0-30 ,000 acre of aquaculture feed.

Related post: Shrimp Feed Mill

When picking floating fish feed making maker, we must initially recognize the many characteristics of water feed:

Tiny pellet dimension. As a result of the short gastrointestinal system of water animals and also associated physiological features, in order to quicken digestion as well as absorption, fish feed ought to be crushed with a smaller pellet dimension than animals and chicken feed.

High in healthy protein and reduced in carbohydrates. The healthy protein web content of animals as well as chicken feeds is generally less than 20%, while the protein content of water pet feeds is mainly 30% to 40%, as well as the protein material of turtle and eel feeds is as high as 65% to 70%.

The pellet feed made by drifting fish feed pellet equipment has a portable structure, high cohesiveness as well as water resistance. For shrimp feed, the stability of the pellet feed in water for greater than 2 hours is required to create top notch marine feed. Only using extruded fish feed can attain water security sex-related impact.

It must rely upon scientific as well as affordable processing innovation and also integrate it with advanced, reliable and also stable floating fish feed pellet maker. In this regard, the option of floating fish feed pellet maker is especially crucial.

Related post: https://www.richipelletmachine.com/shrimp-feed-mill/

1. Why make use of floating fish feed pellet machine?

With the development of aquaculture in the direction of range, intensification and specialization, its demands for aquaculture feeds are obtaining greater as well as greater. Standard powder substance feeds, granular compound feeds as well as other kinds of compound feeds all exist the negative aspects of bad water stability, quick sedimentation, easy to cause feed loss and water pollution, etc, have actually come to be more and more unsuitable for the growth of contemporary tank farming.

And extruded fish feed made by floating fish feed pellet maker fixes these disadvantages, a growing number of aquaculture farmers and also drifting fish feed mill sets up floating fish feed extruder device. Damp process twin-screw floating fish feed pellet device, the output can get to 1800-2500kg/ h in one hr.

The dry process does not need a boiler. The wet process of drifting fish feed pellet equipment calls for a central heating boiler, with high result and also consistent aging, which can be selected according to customer requirements. The raw products are generally corn and wheat bran, and also fish dish as well as various other formulas can be added according to customer requirements.

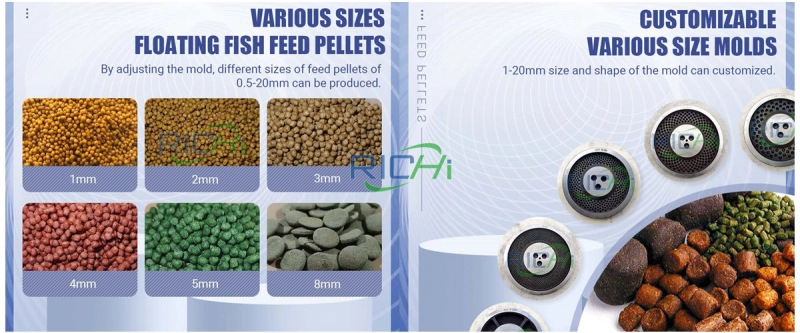

The dimension variety of fish feed that can be produced: 1mm, 1.5 mm, 2.0mm-10mm (customized mold and mildews according to client requirements).

Range of application: It can generate and also refine catfish feed, lawn carp feed, crucian carp feed, tilapia feed, ornamental fish, turtle feed, rabbit feed, bullfrog and also other aquarium feed pellets. Floating fish feed, sinking fish feed.

Related post: poultry feed plant cost

2. Benefits of floating fish feed pellet device.

After greater than 10 years of experience and also continuous research study, the screw of the floating fish feed extruder produced by Richi Machinery has high wear resistance, and is made from special materials and also unique procedures. Greatly reduces the reproducing expense of handling families.

The transmission of the twin-screw drifting fish feed pellet equipment embraces the very same grinding equipment as the automobile, which has high wear resistance and low failure price. There will certainly be no damage after 4 or five years of use.

Twin-screw aquaticfloating fish feed pellet device is made up of feeding system-- extrusion system-- rotary cutting system-- heating unit-- transmission system-- control system.

Each part of floating fish feed pellet device has been made very fairly in Richi Machinery combined with 25 years of manufacturing experience. Such as the rotating reducing component, the item cutting is secure, and also the spiral components have high wear resistance.

The feeding system, rotating reducing system as well as drive system all embrace frequency conversion speed regulation, which can run smoothly and also save power.

Automatic lubrication of floating fish feed pellet equipment lowers power consumption and extends life span.

Our feeding system of drifting fish feed pellet maker adopts double-screw forced feeding, the feeding is uniform and wide.

The screw of floating fish feed making maker is made of high wear-resistant alloy steel 38CrMoAl, which has actually been nitrided.

High toughness and use resistance. Anti-fatigue and also lengthy service life.

Various screw length-to-warp ratios are suitable for various process needs.

3. Process circulation of floating fish feed mill.

Feeding-- crushing-- barrier container-- superfine mill-- vibrating screen-- bin-- screw feeder-- double shaft paddle mixer-- barrier bin-- screw conveyor-- bucket elevator--- wet drifting fish feed pellet maker-- Air Conveyor-5 * 8m Heavy Steam Clothes Dryer-- Cooler.

Drifting fish feed mill configuration:.

Small drifting fish feed assembly line consists of powder mixer, floating fish feed pellet maker, clothes dryer, oil spray flavoring equipment, etc Tool floating fish feed production line consists of pulverizer, powder mixer, drifting fish feed pellet machine, clothes dryer, cooler, vibrating display, gas injector, product packaging, and so on Massive floating fish feed assembly line consist of automated batching, squashing and also mixing, puffing and also drying out, drifting fish feed pellet device, cooling and also oil spraying, automated packaging, and so on

4. What is extruded feed?

Extruded feed is a brand-new modern technology of feed handling. It is a procedure of processing into feed through extrusion to create high temperature and high pressure.

① First, floating fish feed pellet maker was created in the 1930s for the manufacturing of pasta. It was later customized to produce pet feed and also human food such as snacks, sweet.

Because of its high flexibility, the extrusion process can produce foods of varying degrees of fat, thickness, sizes and shape, as well as it can additionally generate a wide array of feeds, including floating, semi-floating, as well as sinking feeds.

Extrusion modern technology of drifting fish feed pellet machine has actually been used to produce shrimp feed since the early 1970s, but it has actually not been widely made use of since it swells after extrusion, creating the feed to drift on the water for extended periods of time.

In order to minimize the buoyancy of the feed, fish feed manufacturers have to decrease the starch content, which results in increased raw material prices. Yet with the constant growth of drifting fish feed pellet equipment extrusion technology.

These imperfections have actually been substantially boosted, such as readjusting the style and also rate of the screw, transforming the arrangement of the mold and also the components of the vacuum warmth sink. Presently, it is feasible to generate extruded feed for shrimp with a density equal to that of pelleted feed.

Extruded feed made by floating fish feed pellet machine can lower the cost of basic materials to a certain level. First, a great deal of wheat starch can be replaced with less costly starch.

② Secondly, because of the moisture, temperature level and high pressure of the floating fish feed pellet maker, quickly digestible substances can be generated, which assists in the food digestion and also absorption process.

After the extruded feed is increased, it can generate a substance that boosts cravings. This produces the possible to produce a extra appealing shrimp feed without depending on pricey protein. As a result of the continual progression of extrusion innovation, the expense of creating extruded feed is anticipated to be additional reduced.

At the same time, the advantages of extruded feed in sterilization are unrivaled by pellet feed. Therefore, drifting fish feed pellet maker are expected to come to be progressively preferred.

For details please contact: feed machine

WhatsApp:86 138 3838 9622

Email:[email protected]

profile/1956richimachinery.jpg

RichiMachine

Timber Pellet Mill Available & Supplementary Tools

~10.0 mins read

Wood pellet mill available is a brand-new type of equipment for creating biomass pellets. Today, when energy is progressively scarce and the atmosphere is weakening, straw sawdust pellets have actually come to be a replacement for coal, oil as well as gas.

The complete collection of biomass timber pellet mill for sale can make rice husks, sunflower seed husks, peanut coverings as well as various other melon and also fruit coverings; branches, tree stems, bark and other timber scraps; different plant straws; rubber, cement, ash residue The materials and wastes are extruded as well as created right into combustible pellets.

The vertical ring die wood pellet mill up for sale generated by Richi Equipment has the attributes of special design, sensible structure and also long service life. This product appropriates for pressing materials that are difficult to bond and form. Processing plants, fuel plants, plant food plants, chemical plants, etc, are excellent compression as well as densification molding tools with small investment, quick result, as well as no danger.

Related post: Wood Pellet Production Line

1. Attributes of timber pellet mill available:

( 1) Energy conserving, the firm understands fully automatic feeding, and embraces frequency conversion to control the conveyor and feeding screw, so that the primary engine motor is in an suitable functioning state, which not just protects the electric motor however additionally makes full use of the motor power.

( 2) The wear price is reduced, the pressure roller is forged from alloy steel, as well as the heat carburizing therapy after ending up, the hardness can reach 60HCR, and also the life span is much longer.

( 3) The product of the wood pellet machine has solid versatility. After years of sales experience of our firm, the mechanical control and also mold compression proportion are changed according to various products of consumers, to ensure that the product is more suitable for customer needs.

( 4) The mold has a long life span. The mold and mildew of the wood pellet mill to buy is constructed from special stainless steel by forging, finishing, warmth treatment and fine grinding. Due to the unique mechanical homes of stainless steel, the mold is smoother as well as a lot more wear-resistant.

( 5) The maintenance is simple as well as hassle-free. The automated circuit control system is embraced, and the grease is immediately added at routine periods to stay clear of the troublesome manual procedure and also incorrect upkeep, and also make the bearing a lot more resilient.

Related post: Canada 2-3T/H Wood Pellet Plant

2. Supporting equipment of timber pellet mill for sale

In the production of timber pellets, the equipment that can be utilized with the wood pellet mill consists of:

( 1) Wood Sawdust Crusher

Sawdust pulverizer is an suitable mechanical equipment for creating timber chips and edible fungi base products. It can refine wood, branches as well as various other resources right into timber chips at one time. It has the advantages of reduced financial investment, low energy intake, high efficiency, excellent economic benefits, as well as upkeep Convenience as well as other advantages, it is a special equipment for the growth of edible fungi manufacturing or for the production of particleboard, sawdust board and also high-density board resources. This devices is utilized in the front area of the timber pellet mill offer for sale.

Scope of application of sawdust shredder:

This timber crusher machine can refine all sort of wood, timber scraps, branches and forks, timber chips, board bordering, bark, bamboo as well as bamboo bark into sawdust and also wood chip products at once, as well as the ended up products can be directly used for shiitake, mushroom, fungi It can also be utilized for the production of basic materials for particleboard, sawdust board and high-density board.

( 2) Chipper

Drum timber chipper is a unique equipment for creating high-quality wood chips. It is mostly used for wood chip manufacturing in timber pellet mill plant, paper mills, particleboard manufacturing facilities and also fiberboard factories. It can cut logs into premium wood chips with consistent dimension and density, as well as can additionally reduce branches, forks, plates, and so on basic materials. The products are commonly made use of by residential as well as international users with the characteristics of steady efficiency, reliable top quality and high price performance.

Related post: pellet mill

The drum chipper can reduce logs, branches, slats, bamboo as well as other materials right into timber chips of certain specifications. The tools has advanced structure, consistent size and density of completed products, steady use and also hassle-free upkeep. It is made up of seat, blade roller, feeding roller, feeding conveying, hydraulic system, as well as releasing communicating.

Among them, the machine base is welded with high-strength steel plate, which plays the major function of sustaining and also increasing the mechanical stamina; both blades on the knife roller are chosen the blade roller by the pressing block and the pressing screw; the feed roller assembly according to the dimension as well as size of the feed, it can float up and down within a specific range with the help of the hydraulic system; the cut qualified sheets fall through the mesh display holes and are transported out by the bottom conveyor belt; at the same time, the hydraulic system can additionally be utilized for tools upkeep, replacement of devices, and so on. This devices is utilized in the front section of the timber pellet mill offer for sale.

(3) Timber splitter

The wood splitter is an important complementary tools in the wood chip processing sector, as well as there are 2 series of vertical and straight. Its feature is to utilize the hydraulic working concept to split tree stumps, huge tree branches, huge log sectors and hard timber to satisfy the demands of the chipper feeding dimension, or to divide the raw materials right into materials for other functions. The hydraulic cyndrical tube stroke varies in size according to the actual use the consumer. The nominal stress is 30 lots, 35 heaps, and also 50 bunches.

The timber splitter is an important material prep work device in the wood pellet mill plant, paper market, synthetic board market, wood pulp handling as well as various other industries., It has the features of high pressure, time conserving, labor conserving, practical framework, solid and resilient, high outcome, very easy procedure and even more security. This equipment is utilized in the front section of the timber pelletizer equipment.

( 4) Theme crusher

The building formwork crusher is a timber crushing tools developed by our company. It has actually been continuously introduced and also improved for several years. It is currently the 5th generation product. For a long time, our business has actually continuously interacted as well as recognized with customers, and taken in the actual usage experience and troubles of customers, to ensure that the security of the feeding system of the equipment has been constantly boosted; the framework of the crushing cutter head is more reasonable; the discharge is boosted by magnetic separation. This devices is used in the front area of the wood pellet making equipment.

The tools itself can crush steel bars and also iron nails below Φ10 as well as iron sheets and also steel plates listed below δ3mm, eliminating the time-consuming and also laborious difficulty of hands-on option. At the same time, the structure of the crushing system of the design template crusher created by our firm is more stable and also affordable, and the upkeep of the drum chipper and various other equipment is difficult and the difficulty of frequent substitute of accessories. The discharge magnetic separation device embraces a effective permanent magnet to remove iron, which has no power usage, and also the iron elimination can reach more than 90%.

At the same time, the pallet crusher equipment has a small framework as well as is very easy to install, and also the feeding port reaches 300 × 1300mm, which can directly crush waste wood boards, constructing themes, wooden pallets, as well as logs below Φ400.

( 5) Clothes Dryer

The dryer is a kind of drying out tools developed as well as produced by our business for timber handling devices. It is generally utilized for drying sawdust, wood chips as well as various other light particular gravity products. The product is totally blended with the hot air when passing through the pipeline, and is drawn out by the fan. Due to the large contact location in between the product as well as the hot air driven by the follower, the drying out efficiency is considerably raised. Given that the whole drying out process of the air flow dryer is performed in the pipeline, each time the product passes through a bend, it will certainly go into a buffer zone with a larger size, so that the material stays longer and the drying is more adequate. This tools is used in the front section of the wood pellet mill to buy.

Compared to the tumble clothes dryer, the air flow clothes dryer can be constructed in a straight line or zigzag. Given that the drying process is performed in the pipe, even if it is only half the quantity of the tumble dryer, the reliable drying out range is the same as that of the tumble clothes dryer. Greater than twice as long as the dryer. Naturally, the air dryer is not as good as the tumble dryer for products with huge specific gravity (such as rocks) as well as products that are very easy to harden (such as chicken manure, river sand). The price is reduced, the drying out rate is quick, and also the airflow clothes dryer is better than the tumble dryer with a size of greater than 10 meters and one meter.

( 6) Peeling off maker

The debarker is a series of log processing products, mainly made up of a feeding mechanism, a discharging device, a blade roller, a transmission system, a chassis and also various other components. It can additionally complete the peeling off therapy of some icy and dried products. It is commonly made use of for peeling wood such as poplar, cypress, paulownia, eucalyptus, oak, and elm. This equipment is used in the front section of the wood pellet mill up for sale.

The peeling equipment breaks the shortcomings of the conventional drum-type timber peeling machine, which has to be stopped for discharging as well as feeding. The veneer outlet as well as the timber electrical outlet are separated to understand continual job, and the entire process from feeding → peeling → wood output → re-feeding → re-peeling → timber result is continuous, and also the circulation procedure is realized. About different timber types, the peeling impact can be adjusted, and also the wood can be peeled off on the machine for different lengths, bends, as well as moisture. The single-machine trough peeling off equipment can peel 35-50 tons of logs a day, which significantly conserves workforce.

Features of timber peeling equipment:

① Using an open silo, which can be fed from one end as well as released from the other end, conquers the imperfections of the existing drum peeling off machine for feeding, discharging, and segmented work, as well as has high job performance.

② As a result of the effect of the teeth on the timber segment, the timber section not just makes a circular movement in the housing, but likewise rotates around itself, so the peeling off effectiveness is high, as well as the tree varieties that are difficult to peel off such as eucalyptus poplar have a better peeling rate

③ The peeling maker has solid adaptability to timber, and can peel off wood segments of various tree species, diameters, lengths as well as forms. Since the timber segments do rotating movement and also uneven pounding, the scooped part of the curved timber sector can additionally be really comparable to the peeling teeth. Great touch. Consequently, the stripping rate for bent logs is a lot higher than various other drum kinds.

④ Since the big case is taken care of, so the power usage is reduced, the failing price is low, the upkeep workload is little, and the resonance and sound are a lot lower than that of the drum peeling equipment. Easy to mount as well as utilize.

( 7) Belt conveyor

Compared with regular belt conveyors, belt conveyors are preferable for communicating loosened and also light-weight materials, such as timber chips, shavings, grain, etc. This tool is used to link various other equipment and timber pellet mill up for sale.

Compared with the framework belt sharing, the trough communicating has enough depth of the trough, and the light details gravity product can be conveyed faster, as well as it is not ideal for spilling.

At the same time, the feeding trough of the trough belt conveyor can be personalized according to customer needs such as depth, length, width as well as other technological demands, as well as can additionally be completely enclosed to lower dirt pollution during devices procedure.

( 8) Bucket elevator

Pail elevators are generally targeted at the upright conveying of granular materials as well as powdered products. Compared to belt conveyors, because of the vertical communicating method, they have extra benefits than belt conveyors in terms of sharing height as well as floor area.

Our company generally generates three sorts of pail lifts: 160, 250, and also 350. We can personalize various heights (up and down 3 meters), products (carbon steel, stainless steel), transmission approaches (chains, tapes) as well as hoppers according to client needs. Product (plastic, carbon steel, stainless steel). This device is made use of to connect various other tools and also the timber pellet mill up for sale.

For more: Richi Machinery

Advertisement

Link socials

Matches

Loading...