RichiMachine

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Wants to meet Just Friends

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

Biomassdevicesiscommonrepofbioenergy

~4.6 mins read

As the text of the biomass energy market, biomass pellets have played an important role from the very start. The raw product entering journalism chamber of the biomass devices is extruded into biomass pellets by the turning of the die wheel.

The outcome and performance of the biomass pellet machine are the basis for selecting a biomass devices. The good efficiency and also high output of the biomass pellet machine guarantee the earnings as well as growth of the biomass power market, advertise the rapid growth of environmental protection, as well as are an efficient tool to advertise environmental management.

The natural compounds thrown out in the whole agricultural production procedure are called agricultural wastes, which generally include: plant straw as well as animals manure. The large quantity of organic waste generated in agriculture each year can not be totally utilized, which not only inhabits space, but also triggers significant waste of resources.

Related post: 1-1.5t/h wood pellet production line

The primary plants worldwide are corn stalks, rice husks, peanut husks, cotton stalks, etc. Can these different raw materials be made use of to complete the work with one device? With the growth of economy, environment-friendly round economic situation is progressively supported, which is an inescapable fad in the process of financial advancement. The biomass tools has a great recycling price for agricultural waste.

Although these farmland wastes can be pressed by the exact same biomass fuel pellet maker, the sustaining devices as well as financial investment dimension corresponding to each basic material are various. There are three requirements for making granules: the raw product is powder, the dampness can not exceed 15%, and the dimension of the raw material is smaller than the pellet size. As a result, the preliminary crushing as well as squashing preparations of resources need to remain in area. Just in this way can we make full use of farming waste.

Take China as an instance. China is a large agricultural country. Tens of countless tons of straw are piled up and lost yearly, and also hundreds of countless lots of coal are shed yearly. The supply is starkly in short supply. The biomass devices is a common agent of biomass power. It's difficult to do well.

Agricultural and also forestry deposits such as timber chips, straws, as well as building templates are all raw materials for biomass devices. Biomass fuel pellets have wonderful possible for energy usage; Market development is excellent; create and also enhance biomass fuel innovation as well as gas burning innovation, provide more incentives as well as support policies for gas pellets, establish more briquette gas presentation bases, restrict the unreasonable use of coal, as well as enhance individuals's environmental management recognition, the growth of biomass pellet fuel has great market potential customers.

Biomass pellet fuel is pulverized, pressurized, compressed as well as formed to become strong round pellet gas. Pellet fuel is made by extruding raw materials such as wood chips and also straws by utilizing biomass fuel pellet press rollers as well as ring die under regular temperature conditions.

Pellet gas is a kind of biological energy. It can replace fire wood, fuel oil, coal, dissolved gas, etc. It is widely made use of in home heating, living stoves, warm water central heating boilers, industrial boilers, biomass nuclear power plant, etc, lower air discharges as well as pollution.

The thickness of the raw material of pellet fuel is generally about 0.6-0 .8, the density of the pellet after molding is greater than 1.1, the calorific value can reach 3400 ~ 4800 kcal, the thickness is high, the particular gravity is large, the quantity is little, the burning resistance, the sulfur material is reduced, and also the storage is convenient. and also transport. At the same time, its combustion performance is substantially improved, which brings particular work troubles as well as economic advantages.

Why biomass gas pellets are various from other gas?

As we all understand, the exploitation of electrical power and also the ignition of coal are both major reasons for air contamination currently. The storage of some non-renewable resources has actually dropped dramatically, however biomass gas has no result at all. Everybody thinks it is extremely odd. Let me tell you about the benefits of biomass gas pellets that are different from various other gas.

Related post: 3T/H wood pellets plant

( 1 ) Basic material: The raw materials of biomass gas are mostly from the wastes of the growing market. Agricultural as well as animal husbandry resources consist of farming as well as manufacturing and also processing wastes and numerous power and energy plants. For instance, corn stover and also peanut husks can be utilized as basic materials for the manufacturing as well as processing of biomass fuels by biomass equipment.

This not just reduces the environmental pollution triggered by waste burning or dissolution of area farming as well as forestry, however also enhances farmers' revenue and produces employment problems. Compared with basic raw materials, biomass gas not only brings economic development rights and interests to clients, yet likewise becomes a design for ecological environmental protection. look at here now

( 2 ) Air pollution discharge: When fossil power is ignited, a large amount of co2 is launched, additionally, a huge quantity of residue, sulfur metal oxides as well as nitrogen oxides will certainly be created. Biomass gas have low sulfur material and reduced carbon dioxide usage.

( 3 ) Heat generation: Biomass fuel can further boost the ignition features of wood products, which is a lot more calorific than coal ignition.

( 4 ) Monitoring method: The fuel specification refined by biomass fuel pellets is little, does not inhabit added interior area, as well as conserves the cost of transportation and storage space systems.

Richi Equipment is a company with years of experience in biomass pellet mill available. The biomass devices, sawdust pellet equipments, straw pellet machines and also other equipment created by the business have actually been recognized by many individuals. To buy biomass power equipment, please select Richi Equipment.

For details please contact: pelleting machine

WhatsApp:86 138 3838 9622

Email:[email protected]

profile/1956richimachinery.jpg

RichiMachine

Rawmaterialsforusingwoodbamboopelletequipment

~5.0 mins read

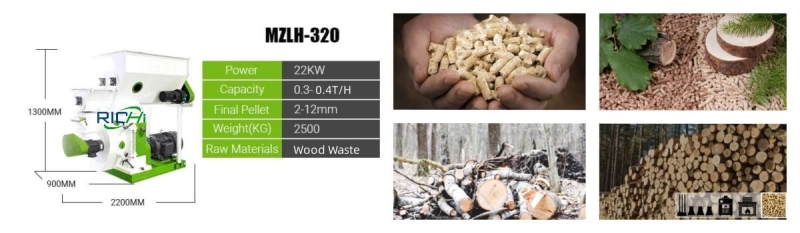

For everybody, the timber pellet equipment need to not be a strange thing. The supposed wood bamboo pellet equipment is a device that makes timber chips, straw as well as various other raw materials into biomass fuel pellets, which understands the reuse of sources. Its look satisfies the demands of environmental management of the times, and normally it has likewise been recognized by the public. Today, the editor will certainly share with you the raw materials that can be refined by the hardwood bamboo pellet machine.

1. Resources that can be processed by wood bamboo pellet machine:

( 1) Residues of plants: consisting of cotton straw, wheat straw, rice straw, corn straw, corn cob and also some other cereal straws, and so on. Amongst them, corn cob can be used as the main raw material for the production of xylitol, furfural and other chemical items; different straws such as corn stalk, wheat orange, cotton stalk can be processed as well as combined with material to make fiber board; straw can also be directly gone back to the field as plant food, and so on.

Related post: bamboo pellet machine

( 2) Wood chips: The bit dimension of wood chips is very good. The pellets made from wood chips have stable return, smooth pellets and high firmness.

( 3) Small shavings: Due to the fact that the fragment size is relatively huge, it is hard to get in the wood pellet equipment, and it requires to be squashed prior to usage.

( 4) Sand light powder in board factory as well as furnishings factory: sand light powder has a light proportion as well as is simple to block. It is suggested to mix wood chips with each other for granulation, and the proportion can be about 50% to achieve the most effective impact.

( 5) Leftovers of wooden boards and timber chips: The leftovers of wood boards as well as timber chips can just be utilized after being squashed.

( 6) Coarse product: The size of the fiber must be managed, and also the basic length should not go beyond 5mm.

In the working process of the wood bamboo pellet device, the physical molding of the fiber product is entirely dependent on the physical molding of the fiber product without adding any binder. The major elements of biomass raw materials such as straw and also timber chips are cellulose, hemicellulose, lignocellulose and also its material, wax and more.

Related post: https://www.pellet-richi.com/wood-pellet-machine/bamboo-pellet-production-pelletizer.html

Among the above parts, lignocellulose is commonly taken into consideration to be the best innate binder in living organisms. When the temperature gets to concerning 70 ℃ ~ 110 ℃, the lignocellulose will become soft and also the adhesive force will certainly begin to raise. Right now, a specific stress is applied outside, which can make it very closely bond with cellulose, hemicellulose, etc, directly with biomass pellets are glued to every other. After cooling down, the strength raises, and rod-shaped, small-block as well as granular biomass strong gas can be acquired.

2. Contribution of hardwood bamboo pellet maker to environmental protection

Hardwood bamboo pellet equipment is a kind of straw pellet machine. It primarily utilizes agricultural and also forestry wastes such as branches and sawdust as raw materials, and also processes them right into designed biomass pellet gas, which is made use of in various markets. As people put forward higher needs for life and production, the hardwood bamboo pellet maker has acquired a broader advancement space, as well as its functions have actually additionally been enhanced, as well as at the same time, the development and also application fields will certainly be increased.

The biomass pellet fuel generated by the hardwood bamboo pellet machine has the attributes of tidy burning, high efficiency and energy saving, as well as environmental protection. Industrial waste has really high environmental protection value, as well as at the same time saves sources. With the improvement of individuals's environmental management principle, the production technology of timber pellet machine is additional created, and its functions are progressively diversified, which not just understands turning waste into prize, but additionally improves the value of plants, yet additionally advertises the environmental atmosphere as well as drives economic advancement.

Related post: bagasse pellet machine

3. Benefits of sawdust hardwood bamboo pellet maker:

It can refine various timber chips, straw, chaff as well as various other resources;

High output, reduced energy intake, reduced noise, reduced failure price, solid tiredness resistance, and also constant production;

Using different molding technologies such as chilly pushing and also extrusion molding, the biomass pellets have a lovely look and small framework;

Utilizing special top notch materials and also advanced attaching shaft transmission gadget, vital components are made of top quality alloy steel and wear-resistant products, with long life span.

4. The distinction in between hardwood bamboo pellet maker and feed pellet maker:

When buying a hardwood bamboo pellet equipment, several consumers will inadvertently purchase the wrong one and buy an pet feed pellet device. RICHI Machinery advises you that although hardwood bamboo pellet machine and also feed pellet machine are both pellet equipments, their application extent is various, so the distinction is rather apparent.

In terms of feeding method, the mold and mildew of the hardwood bamboo pellet machine is laid flat, the mouth is up, and also the product straight gets in the pelletizing mold inside out, while the mold of the feed pellet machine is securely put; click here for more

When pushing, the wood bamboo pellet device maker revolves the pressing wheel as well as the mold is fixed, so the pellets will certainly not be crushed twice, while the feed pellet maker turns the mold and mildew, the pressing wheel is repaired, and also the outcome of the feed is reasonably high;

In terms of structure, the wood bamboo pellet maker comes from the upright ring die pellet maker. They are divided by the pushing wheel, so the security is higher. The feed pellet equipment is a straight ring die pellet equipment, as well as the pelleting chamber is sealed.

Additionally, there are many distinctions in between wood bamboo pellet devices as well as feed pellet devices, and also customers need to distinguish them correctly.

The use of wood pellets not only resolves the storage space of waste, but additionally brings new benefits. RICHI Pellet Equipment is a professional supplier of wood bamboo pellet machines, straw pellet makers as well as sawdust pellet devices. Welcome clients from throughout the world to visit our manufacturing facility!

For details please contact: pelletizer

WhatsApp:86 138 3838 9622

Email:[email protected]

Advertisement

Link socials

Matches

Loading...