RichiMachine

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Wants to meet Just Friends

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

Mainfeaturesofaquaticfloatingfeedmaker

~7.1 mins read

Today, marine floating feed equipment technology is incredibly popular in the production of aquafeeds, as it can be used to produce a range of feeds, whether drifting or sinking, depending on the requirements of each types. On top of that, the extruded feed made by marine drifting feed device has less debauchment and high efficiency, aiding to boost digestibility.

Throughout the marine floating feed machine extrusion process, systems such as temperature, moisture, pressure will boost starch gelatinization, break down as well as soften the cell wall and also launch some quickly absorbable materials, therefore advertising the digestion and also absorption of farmed animals.

Via water drifting feed machine extrusion modern technology, it is feasible to inhibit certain protease inhibitors (such as antitrypsin), ruin virus in resources or change healthy protein residential or commercial properties to additional boost the contact with enzymes in fish and also shrimp, assisting to digest food more conveniently.

Related post: Sinking Fish Feed Machine

Extruded feed made by water floating feed maker can manage the web content of compounds and also assist better cleansing. At the same time, the longer stablizing time in the water (12-36 hours) helps farmers to observe and control the feeding schedule.

Although extruded feed made by drifting fish feed making equipment has obvious advantages over pelleted feed, the preliminary financial investment cost of extruded feed manufacturing is greater, leading to higher feed costs.

But also for premium fish farming, increasingly more people are taking note of the market prospect of premium fish feed.

1. Main features of water drifting feed device.

Feeding, rotary cutting, and also main drive all adopt frequency conversion rate regulation system, which has strong power, secure procedure, energy conserving, high water manufacturing effectiveness, sturdy tools, reduced failure price, and convenient operation and maintenance.

The screw of drifting feed maker is made of alloy material by special process, the life span is 3-4 times longer than that of residential comparable equipments, and the cost of generating feed is reduced; the segmented consolidated screw is suitable for a wide range of resources and also more diverse items.

Automatic lubrication system of the floating feed equipment reduces power intake and prolongs life span.

The feeding system takes on spiral forced feeding, and the feeding is consistent as well as vast. It can be furnished with an automated feeding system. The feeder is a screw communicating variable frequency rate control to readjust the feeding amount to manage the puffing output (quantitative feeding, as well as can properly prevent the material from curving).

Direct bearing tool change system, adjust the device precisely and also quickly.

The twin-screw of drifting feed device has self-cleaning function, and using equipment is extra practical and practical.

Update the configuration of different equipment technology and also equipment to make the output of the twin-screw drifting feed maker bigger.

Different screws and also length-diameter ratios can fulfill various production processes.

Aesthetic automated temperature level control system to make temperature control more instinctive and criteria a lot more precise.

The total drifting feed device arrangement The procedure of the fish feed pellet extruder is more instinctive and the maintenance is easier.

Dry blowing process takes on self-heating approach without steam system, which is more in line with the actual demands of customers.

No adhesive is required to refine the drifting feed, and also it can preserve security in water for more than 12 hrs.

Small and moderate equipment is especially appropriate for clinical study institutions, unique breeding farms or tool and tiny feed manufacturing facilities. There are also particularly tailored experimental twin-screw floating feed makers readily available for clinical study devices.

Related post: cattle feed plant price

2. The difference between pellet feed as well as squeezed out feed.

With the development of the drifting fish feed processing sector, two extensively used modern technologies currently used to produce aquafeed are pelleting as well as extrusion by floating feed machine. Contrasted to all-natural lures, such feeds have greater dietary web content and also security, less dampness, easier storage, fewer microorganisms, as well as longer storage times.

Pelletizing by floating feed equipment is a method of compressing tiny pellets of resources into larger pellets, throughout which humidity, temperature level and pressure can significantly influence the high quality of the feed.

Among the main advantages of pelleted feed is reduced manufacturing prices. Nevertheless, it has some downsides.

One of the biggest drawbacks of pelleted feed is that it sinks faster and liquifies swiftly in water (according to stats, regarding 10-15% of feed is thrown away), which indicates higher feed expenses, reduced farming revenues, and simpler cause water air pollution.

3. Choose pellet feed or extruded feed?

Farmers, choose pellet feed or extruded feed?

When picking feed, farmers must think about the qualities of different marine species as well as feeding routines. Due to the fact that the routine of shrimps as well as crabs is to discover food near the bottom, and after that eat the food gradually, so the food ought to not be as well hard and not quickly soluble in water. Recommended Site

As a result, extruded sediment by drifting feed device is the most effective option because it is soft and also difficult to dissolve in water, and also it is convenient for shrimp and also crab to eat, reducing feed waste and also reducing water air pollution.

Specifically in extensive shrimp farming, squeezed out feed should be dominant, due to the fact that it is simpler for shrimp to digest healthy protein from extruded feed, which reduces feed waste as well as advertises far better protein absorption.

At the same time, we can also boost the absorption rate of the feed by including advantageous bacteria or boosting gastrointestinal products to the feed.

Nevertheless, from a long-term perspective, using extruded feed, which is made by floating feed device will certainly increase the price, and if the fish use extruded feed in the mature duration, it might result in fish fat, huge tummy, inadequate stress capacity, not appropriate for long-distance transportation, and so on, resulting in a small cost at the time of sale.

Consequently, in the process of tank farming, when numerous farmers use feed, they frequently make use of a combination of pellet feed and also extruded feed, which not just manages water quality, lowers feed deposits, however likewise improves performance as well as financial benefits.

At the same time, the tank farming sector is advertising the additional advancement of both feeds because of their respective benefits.

4. Installation of drifting feed device.

( 1) Installment of drifting feed device pipe rack.

The option of the setup position of the pipeline rack depends on the website place, but it ought to not be as well much from the main engine. Much from the primary engine will trigger waste of materials during pipeline link on the one hand, and create the hysteresis of the control system on the other hand.

If the installation place on site allows, the most effective position of the pipeline shelf is to be directly behind the major engine and conditioner, parallel to the primary engine, and also regarding 1 meter far from the primary engine (there is a specific maintenance space), while making sure that the pipe rack is readjusted upwards. The setting of the heavy steam line interface of the conditioner gets on the side of the conditioner.

In order to help with the cleaning of the ground and the discharge of waste water in the future, the pipeline rack ought to be raised by about 10 cm during installment. In the installation of each shutoff in the pipeline, the setting of the shutoff wheel must satisfy the demands of hassle-free procedure for floating feed equipment.

( 2) Installation of floating feed machine control box.

In order to help with the procedure, the setup setting of the on-site control box should be picked near the bypass, and a certain space should be scheduled between the bypass and also the control box to momentarily put the wastes moving from the bypass.

The distance in between the regularity converter of the cutting electric motor and also the rotary positioner of the on-site cutter must not be too far. It is controlled by voltage. If the distance is also much, it will certainly cause voltage variations and also impact the cutting effect.

The distributing temperature display screen tool on the on-site control box is to display the temperature level of each end of the blowing tooth cavity in real time, and the presented temperature series has certain requirements. Area 2 Expansion dental caries ... till the material discharge development tooth cavity, this sequence needs to be taken note of when circuitry the electric control.

Additionally, there are 4 nozzles on the water inlet pipeline of the dual-shaft differential conditioner of floating feed equipment. They control the opening of each nozzle with the electro-magnetic cut-off valve.

The drifting feed machine conditioner inlet nozzle switches over 1 to 4 on the control box represent the conditioners The first nozzle to the 4th nozzle from the feed end.

For details please contact: Pelleting Machine

WhatsApp:86 138 3838 9622

Email:[email protected]

profile/1956richimachinery.jpg

RichiMachine

Advantagesoffloatingfishfeedpelletmachine

~6.5 mins read

1. Characteristics of aquatic feed

There are also multiple setups. Drifting fish feed pellet device can refine numerous marine feeds, such as ornamental fish feed, aquaculture fish feed, and so on. According to the nature of fish feed products, it is separated right into sinking fish feed as well as drifting fish feed; it is an suitable equipment choice for the tank farming sector.

Floating fish feed making maker does not require central heating boilers, occupies a tiny area, and is easy to operate. It is a step-type fish feed assembly line with different yields, rate, the day-to-day result is 1-5 tons, which fulfills the manufacturing demand of 0-30 ,000 acre of aquaculture feed.

Related post: Shrimp Feed Mill

When picking floating fish feed making maker, we must initially recognize the many characteristics of water feed:

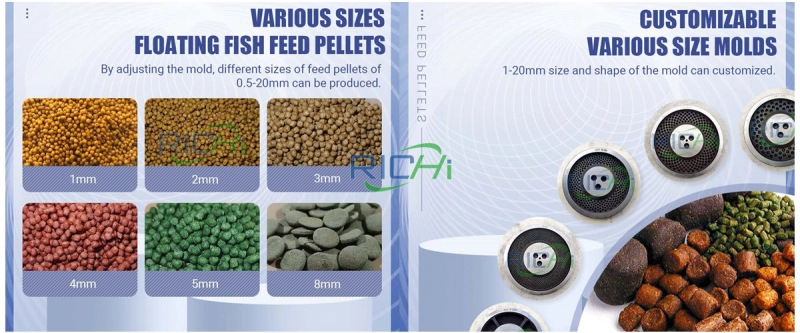

Tiny pellet dimension. As a result of the short gastrointestinal system of water animals and also associated physiological features, in order to quicken digestion as well as absorption, fish feed ought to be crushed with a smaller pellet dimension than animals and chicken feed.

High in healthy protein and reduced in carbohydrates. The healthy protein web content of animals as well as chicken feeds is generally less than 20%, while the protein content of water pet feeds is mainly 30% to 40%, as well as the protein material of turtle and eel feeds is as high as 65% to 70%.

The pellet feed made by drifting fish feed pellet equipment has a portable structure, high cohesiveness as well as water resistance. For shrimp feed, the stability of the pellet feed in water for greater than 2 hours is required to create top notch marine feed. Only using extruded fish feed can attain water security sex-related impact.

It must rely upon scientific as well as affordable processing innovation and also integrate it with advanced, reliable and also stable floating fish feed pellet maker. In this regard, the option of floating fish feed pellet maker is especially crucial.

Related post: https://www.richipelletmachine.com/shrimp-feed-mill/

1. Why make use of floating fish feed pellet machine?

With the development of aquaculture in the direction of range, intensification and specialization, its demands for aquaculture feeds are obtaining greater as well as greater. Standard powder substance feeds, granular compound feeds as well as other kinds of compound feeds all exist the negative aspects of bad water stability, quick sedimentation, easy to cause feed loss and water pollution, etc, have actually come to be more and more unsuitable for the growth of contemporary tank farming.

And extruded fish feed made by floating fish feed pellet maker fixes these disadvantages, a growing number of aquaculture farmers and also drifting fish feed mill sets up floating fish feed extruder device. Damp process twin-screw floating fish feed pellet device, the output can get to 1800-2500kg/ h in one hr.

The dry process does not need a boiler. The wet process of drifting fish feed pellet equipment calls for a central heating boiler, with high result and also consistent aging, which can be selected according to customer requirements. The raw products are generally corn and wheat bran, and also fish dish as well as various other formulas can be added according to customer requirements.

The dimension variety of fish feed that can be produced: 1mm, 1.5 mm, 2.0mm-10mm (customized mold and mildews according to client requirements).

Range of application: It can generate and also refine catfish feed, lawn carp feed, crucian carp feed, tilapia feed, ornamental fish, turtle feed, rabbit feed, bullfrog and also other aquarium feed pellets. Floating fish feed, sinking fish feed.

Related post: poultry feed plant cost

2. Benefits of floating fish feed pellet device.

After greater than 10 years of experience and also continuous research study, the screw of the floating fish feed extruder produced by Richi Machinery has high wear resistance, and is made from special materials and also unique procedures. Greatly reduces the reproducing expense of handling families.

The transmission of the twin-screw drifting fish feed pellet equipment embraces the very same grinding equipment as the automobile, which has high wear resistance and low failure price. There will certainly be no damage after 4 or five years of use.

Twin-screw aquaticfloating fish feed pellet device is made up of feeding system-- extrusion system-- rotary cutting system-- heating unit-- transmission system-- control system.

Each part of floating fish feed pellet device has been made very fairly in Richi Machinery combined with 25 years of manufacturing experience. Such as the rotating reducing component, the item cutting is secure, and also the spiral components have high wear resistance.

The feeding system, rotating reducing system as well as drive system all embrace frequency conversion speed regulation, which can run smoothly and also save power.

Automatic lubrication of floating fish feed pellet equipment lowers power consumption and extends life span.

Our feeding system of drifting fish feed pellet maker adopts double-screw forced feeding, the feeding is uniform and wide.

The screw of floating fish feed making maker is made of high wear-resistant alloy steel 38CrMoAl, which has actually been nitrided.

High toughness and use resistance. Anti-fatigue and also lengthy service life.

Various screw length-to-warp ratios are suitable for various process needs.

3. Process circulation of floating fish feed mill.

Feeding-- crushing-- barrier container-- superfine mill-- vibrating screen-- bin-- screw feeder-- double shaft paddle mixer-- barrier bin-- screw conveyor-- bucket elevator--- wet drifting fish feed pellet maker-- Air Conveyor-5 * 8m Heavy Steam Clothes Dryer-- Cooler.

Drifting fish feed mill configuration:.

Small drifting fish feed assembly line consists of powder mixer, floating fish feed pellet maker, clothes dryer, oil spray flavoring equipment, etc Tool floating fish feed production line consists of pulverizer, powder mixer, drifting fish feed pellet machine, clothes dryer, cooler, vibrating display, gas injector, product packaging, and so on Massive floating fish feed assembly line consist of automated batching, squashing and also mixing, puffing and also drying out, drifting fish feed pellet device, cooling and also oil spraying, automated packaging, and so on

4. What is extruded feed?

Extruded feed is a brand-new modern technology of feed handling. It is a procedure of processing into feed through extrusion to create high temperature and high pressure.

① First, floating fish feed pellet maker was created in the 1930s for the manufacturing of pasta. It was later customized to produce pet feed and also human food such as snacks, sweet.

Because of its high flexibility, the extrusion process can produce foods of varying degrees of fat, thickness, sizes and shape, as well as it can additionally generate a wide array of feeds, including floating, semi-floating, as well as sinking feeds.

Extrusion modern technology of drifting fish feed pellet machine has actually been used to produce shrimp feed since the early 1970s, but it has actually not been widely made use of since it swells after extrusion, creating the feed to drift on the water for extended periods of time.

In order to minimize the buoyancy of the feed, fish feed manufacturers have to decrease the starch content, which results in increased raw material prices. Yet with the constant growth of drifting fish feed pellet equipment extrusion technology.

These imperfections have actually been substantially boosted, such as readjusting the style and also rate of the screw, transforming the arrangement of the mold and also the components of the vacuum warmth sink. Presently, it is feasible to generate extruded feed for shrimp with a density equal to that of pelleted feed.

Extruded feed made by floating fish feed pellet machine can lower the cost of basic materials to a certain level. First, a great deal of wheat starch can be replaced with less costly starch.

② Secondly, because of the moisture, temperature level and high pressure of the floating fish feed pellet maker, quickly digestible substances can be generated, which assists in the food digestion and also absorption process.

After the extruded feed is increased, it can generate a substance that boosts cravings. This produces the possible to produce a extra appealing shrimp feed without depending on pricey protein. As a result of the continual progression of extrusion innovation, the expense of creating extruded feed is anticipated to be additional reduced.

At the same time, the advantages of extruded feed in sterilization are unrivaled by pellet feed. Therefore, drifting fish feed pellet maker are expected to come to be progressively preferred.

For details please contact: feed machine

WhatsApp:86 138 3838 9622

Email:[email protected]

Advertisement

Link socials

Matches

Loading...