RichiMachine

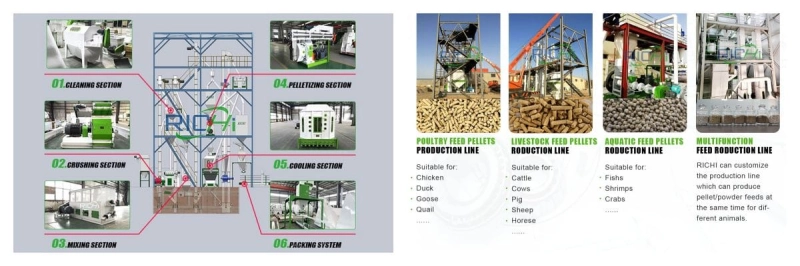

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Wants to meet Just Friends

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

BenefitsofTopQualityFeedMakingMakerForChicken

~5.7 mins read

For users who have made use of the feed making maker for fowl, the advantages of the feed pellet equipment are apparent. The benefits of feed pellet machines are also one of the most frequently asked questions by farmers. Today we will evaluate carefully the upstream and also downstream of the chicken feed pellet making maker and also the advantage evaluation brought by the maker.

Most of us know that in order to boost the quality of feeding, feed is the top concern. In the past, we generally processed the feed into powder and after that fed it, which is not just troublesome to feed, yet also has poor palatability and also low usage price. Currently we utilize the feed making equipment for poultry to process the feed into pellet feed for feeding.

The feed making equipment for fowl is a new sort of machine, which can use illumination electrical power as the power to squeeze out pellets from the die opening under the extrusion of the pressing roller. This technique can easily change the size of the pellets. In addition, the feed pellet device has a simple framework, tiny impact and also reduced noise. Typically, it can be operated with a little understanding.

Related post: chicken feed pellet machine

1. Sorts of feed making equipment for fowl:

Feed pellet devices are divided into 2 kinds: level die and ring die. Generally, ring die feed making makers for fowl are made use of in feed handling. The level die pellet mill can actually amount family usage. Generally, the high quality of feed pellets refined by this tools is not excellent. This is why all poultry feed mills use ring die feed pelleters. According to various user requirements, there are little feed pellet makers, large feed pellet devices and more. When we choose a feed pellet equipment, we can pick according to our real situation. If the per hour production is 10s of kgs to a number of hundred kilograms, level die feed making maker for fowl is great, since this sort of tools is normally not used for commercial purposes. For the need of greater than 1 heap per hr, the ring die feed making device for chicken is generally picked, due to the fact that the high quality of the pellets is great, as well as the life span of the equipment is likewise long. Over time, this is the most economical choice.

2. Just how to pick a feed making device for fowl?

The feed pellets generated by the feed pellet maker are slowly invited by lots of customers. The poultry feed pellet maker will certainly play a antiseptic effect during the operation procedure and minimize the illness rate of animals. In addition, when making feed pellets, different waste plants are blended together, which is abundant in nutrients and pets like to consume, which effectively shortens the growth cycle of livestock and poultry.

The layout and pressure roller of the feed making maker for fowl are typically made from high-alloy wear-resistant products and have a long service life. Therefore, buying a feed pellet machine can typically be used for several years, which is extremely economical as well as useful. Star products on the marketplace currently, such as Richi Machinery's SZLH collection feed making maker for fowl. The fowl feed making maker cost will be various according to different versions as well as different features. You can search when buying. Simply put, what is most important to you is what fits you.

3. Advantage analysis of feed making maker for poultry:

The place of animal husbandry in the growth process of many nations is likewise important. The vital setting of animal husbandry is mirrored in the supply of animal products, food high quality as well as safety, environmental setting security as well as raising the earnings of farmers and also herdsmen. With the rise of people's usage level, increasingly more focus has been paid to the problem of food security.

The medicine deposits in meat products exceed the criterion. Both the residential market and also the international market hold an perspective of question of Chinese meat products. There are problems with feed formulations, and also the faulty feed market is widespread. From time to time there are information direct exposures of faulty feeds, which are polluted with a huge quantity of sand or a big amount of inexpensive feed. Serious damages to the rate of interests of farmers.

With the popularization of feed making device for fowl and the assistance of the policies of numerous countries for the reproducing sector, farmers create feed on their own, from raw materials to formulas, they master the production by themselves, as well as breed them with more confidence and also assurance.

And also fowl devices, currently take lamb feed pellet equipment farming as an example:

For goat dog breeders of a specific scale or tiny and also medium-sized goat farms, it is lengthy and also labor-intensive to make use of blended product to feed lamb, as well as to utilize powdered product to feed sheep, there are also numerous disadvantages. If it can be combined with local feed sources according to the various production needs of lamb to create pellet feed to feed lamb, there will be many advantages.

Related post: cattle feed pellet machine cost

General Boer rams can be pushed (%); corn meal 46, bran 20, bean cake 28, fish meal 4, bone dish 1.3, salt 0.7. Boer ewes press (%); corn meal 53, bran 26, bean cake 18, fish meal 1, bone dish 1, salt 1. Boer lamb by (%): corn flour 48. 5, bran 10, bean cake 36, fish dish 4, bone meal 1, salt 0.5. According to the above feed formula, the pellet feed machine is processed into pellet feed to feed lamb, which not just saves labor and enhances job efficiency, yet likewise advertises growth and also advancement and also enhances the effectiveness of sheep raising. The specific advantages are:

( 1) Labor conserving. The combination is unnaturally prepared as well as fed to lamb. Normally, one worker can feed 28 goats. After feeding pellets, one employee can feed 36 goats as a result of saving the batching time, which improves labor performance 28. 57%.

( 2) Save feed. The lamb are fed with powdered feed, which is easy to spread out and also make the sheep to be choosy eaters. When the wind strikes, the feed will fly up, creating waste, and the feed usage rate is only 92%. After changing to feed pellets, sheep can not be choosy eaters, the feed application rate can get to 99%, and also the feed application rate is raised by 7%.

( 3) The natural waste of agriculture and also forestry has excellent palatability. After the feed is processed, it can increase the scent, boost the appetite of the goat, boost the feed consumption, as well as boost the digestibility of the feed.

( 4) Advertise lamb development and also growth Because the refined pellets have smooth surface, high hardness as well as deep treating, lamb like to consume them. Chewing allows points, high digestion as well as usage price, and also advertises sheep development and also development.

( 5) The powder feed itself has a moisture content of about 15%, as well as it is very easy to take in dampness and also deteriorate as well as agglomerate, so it has no feeding value. After the powdered feed is refined into pellets, part of the wetness is lost, and the processed pellets by feed making device for fowl have a wetness web content of about 13%, which fulfills the standard demands. Under excellent storage problems, the pellets can typically be kept for 3-4 months without degeneration. Forming feed for 2-3 months.

For details please contact: Richi Pellet Mill

WhatsApp:86 138 3838 9622

Email:[email protected]

profile/1956richimachinery.jpg

RichiMachine

Ways To Choose A Floating Fish Feed Maker

~4.6 mins read

In recent times, with the rapid advancement of the economy, the floating fish feed maker has followed closely, and also the fish feed pellet equipment has been demanded by every person. Then there is a problem, that is, how to pick the drifting fish feed equipment Allow's evaluate the three approaches of choosing a fish feed pellet machine.

Related post: 1-20t/h fish feed processing line

1. Methods to pick a drifting fish feed device.

( 1) Look top quality.

The spray paint externally of the shell of the drifting fish feed machine ought to be consistent as well as company, and there need to be no paint leakage, drooping and diminishing. The chrome-plated parts need to be firm as well as brilliantly polished, without peeling as well as rust. Stainless-steel components need to have a smooth surface, no bumps, and ought to be processed with neat sleek patterns.

( 2) Assembly and fastening

Along with checking the attachment of the body and the framework, the electric motor (or diesel engine) and the framework, the floating fish feed maker mostly checks the assembly top quality of the theme locking nut and also the pellet cutter, and also the ring die floating fish feed maker mainly checks Whether the securing bolts of the template are tightened up. And also check the rigidity of the pinch roller bracket as well as squeeze roller.

Related post: https://www.pellet-richi.com/fish-feed-extruder/aquatic-feed-pellet-production-line.html

( 3) Readjust the gap between the die and also the pressure roller wall surface.

2 layers of paper are packed in between the stress roller as well as the internal wall of the ring die, and also it can be pulled out with a little force. After change, make sure to tighten up the changing nut in time and also set up the protective cover.

After confirming that there are no international things in the shield and also the ring die, turn the ring die by hand. Right now, the driven pin should turn briskly, and there is no sticking phenomenon or rubbing noise.

2. Notes:

Directly observe whether there is pounding of the drifting fish feed maker ring die throughout rotation and also whether it will massage versus various other components. Open up the monitoring port for feeding the powder right into the turning cage and examine whether there is any contaminant in the turning cage.

Revolve the cage shaft by hand, the cage shaft should revolve efficiently and also there is no rubbing noise. Repeatedly open and close the ring-molded storage facility door to check whether it is easy to open and shut as well as tightly closed.

Related post: floating fish feed making machine

Particular attention needs to be paid to examining the tightness of the joint as well as the dependability of the securing. The basic requirements are: exact positioning, solid securing, as well as no leakage of powder.

After locking the press chamber door, observe the joint seal of the chamber door from the side. If there is a place where the seal is not tight, the repairing screws of the door joint of the storage facility can be adapted to properly protect against the leakage of powder.

3. Intro of floating fish feed equipment

The drifting feed extruder machine is a feed handling maker that directly presses pellets from smashed products such as corn, soybean dish, straw, turf, rice husk, and so on( 1) Classification of floating fish feed pellet machine

floating fish feed device can be divided into ring die pellet maker, ring die pellet maker and counter-roll pellet equipment; according to manufacturing, it can be split right into: straw feed pellet machine, wheat bran feed pellet maker, soybean meal feed pellet maker, corn straw feed pellet maker, Sawdust feed pellet equipment, etc.

A range of different floating fish feed devices are categorized according to their look and also manufacturing methods.

try this site

( 2) Main efficiency attributes of floating fish feed equipment

Double shaft differential stainless-steel conditioner, as much as 12 factors of steam as well as 6 points of fluid enhancement;

Integrated spindle, very easy to preserve and fix the bearing housing;

The screw and the main shaft are linked by involute splines, which are easy to change and change;

The barrel is installed with a wear-resistant bushing and is equipped with a return water network, which can be heated/cooled, as well as can likewise directly infuse heavy steam or cold water into the barrel;

Spiral constructed from special wear-resistant material, large aspect ratio can make sure constant and stable production of sinking/floating feed of different pellet sizes;

Convenient and fast die substitute system and online flexible reducing tool;

Particularly appropriate for the manufacturing of 2 ~ 6mm floating pellets.

After the material is squeezed out by the floating fish feed machine, it will create soft and soft pellets (the wetness material is 25%~ 30%). Currently, it is far better to utilize pneumatic conveying instead of elevator.

Since making use of elevators can easily trigger the pellets to be broken and also enhance the pulverization rate; using pneumatic sharing can not just rapidly develop a layer of colloidal covering on the surface of the pellets to lower the fragmentation of the pellets, but additionally round the shape of the pellets.

Because of its high wetness material, the product conveyed by pneumatically-driven have to go into the clothes dryer for drying out, to ensure that the wetness web content of the product is minimized to concerning 13%.

I wish the above relevant content concerning floating fish feed device is practical to you. For additional information regarding floating fish feed pellets maker, you rate to consult the personnel of Richi Equipment, we will offer you totally!

For details please contact: Richi Machinery

WhatsApp:86 138 3838 9622

Email:[email protected]

Advertisement

Link socials

Matches

Loading...