RichiMachine

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Wants to meet Just Friends

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

Timber Pellet Mill Available & Supplementary Tools

~10.0 mins read

Wood pellet mill available is a brand-new type of equipment for creating biomass pellets. Today, when energy is progressively scarce and the atmosphere is weakening, straw sawdust pellets have actually come to be a replacement for coal, oil as well as gas.

The complete collection of biomass timber pellet mill for sale can make rice husks, sunflower seed husks, peanut coverings as well as various other melon and also fruit coverings; branches, tree stems, bark and other timber scraps; different plant straws; rubber, cement, ash residue The materials and wastes are extruded as well as created right into combustible pellets.

The vertical ring die wood pellet mill up for sale generated by Richi Equipment has the attributes of special design, sensible structure and also long service life. This product appropriates for pressing materials that are difficult to bond and form. Processing plants, fuel plants, plant food plants, chemical plants, etc, are excellent compression as well as densification molding tools with small investment, quick result, as well as no danger.

Related post: Wood Pellet Production Line

1. Attributes of timber pellet mill available:

( 1) Energy conserving, the firm understands fully automatic feeding, and embraces frequency conversion to control the conveyor and feeding screw, so that the primary engine motor is in an suitable functioning state, which not just protects the electric motor however additionally makes full use of the motor power.

( 2) The wear price is reduced, the pressure roller is forged from alloy steel, as well as the heat carburizing therapy after ending up, the hardness can reach 60HCR, and also the life span is much longer.

( 3) The product of the wood pellet machine has solid versatility. After years of sales experience of our firm, the mechanical control and also mold compression proportion are changed according to various products of consumers, to ensure that the product is more suitable for customer needs.

( 4) The mold has a long life span. The mold and mildew of the wood pellet mill to buy is constructed from special stainless steel by forging, finishing, warmth treatment and fine grinding. Due to the unique mechanical homes of stainless steel, the mold is smoother as well as a lot more wear-resistant.

( 5) The maintenance is simple as well as hassle-free. The automated circuit control system is embraced, and the grease is immediately added at routine periods to stay clear of the troublesome manual procedure and also incorrect upkeep, and also make the bearing a lot more resilient.

Related post: Canada 2-3T/H Wood Pellet Plant

2. Supporting equipment of timber pellet mill for sale

In the production of timber pellets, the equipment that can be utilized with the wood pellet mill consists of:

( 1) Wood Sawdust Crusher

Sawdust pulverizer is an suitable mechanical equipment for creating timber chips and edible fungi base products. It can refine wood, branches as well as various other resources right into timber chips at one time. It has the advantages of reduced financial investment, low energy intake, high efficiency, excellent economic benefits, as well as upkeep Convenience as well as other advantages, it is a special equipment for the growth of edible fungi manufacturing or for the production of particleboard, sawdust board and also high-density board resources. This devices is utilized in the front area of the timber pellet mill offer for sale.

Scope of application of sawdust shredder:

This timber crusher machine can refine all sort of wood, timber scraps, branches and forks, timber chips, board bordering, bark, bamboo as well as bamboo bark into sawdust and also wood chip products at once, as well as the ended up products can be directly used for shiitake, mushroom, fungi It can also be utilized for the production of basic materials for particleboard, sawdust board and high-density board.

( 2) Chipper

Drum timber chipper is a unique equipment for creating high-quality wood chips. It is mostly used for wood chip manufacturing in timber pellet mill plant, paper mills, particleboard manufacturing facilities and also fiberboard factories. It can cut logs into premium wood chips with consistent dimension and density, as well as can additionally reduce branches, forks, plates, and so on basic materials. The products are commonly made use of by residential as well as international users with the characteristics of steady efficiency, reliable top quality and high price performance.

Related post: pellet mill

The drum chipper can reduce logs, branches, slats, bamboo as well as other materials right into timber chips of certain specifications. The tools has advanced structure, consistent size and density of completed products, steady use and also hassle-free upkeep. It is made up of seat, blade roller, feeding roller, feeding conveying, hydraulic system, as well as releasing communicating.

Among them, the machine base is welded with high-strength steel plate, which plays the major function of sustaining and also increasing the mechanical stamina; both blades on the knife roller are chosen the blade roller by the pressing block and the pressing screw; the feed roller assembly according to the dimension as well as size of the feed, it can float up and down within a specific range with the help of the hydraulic system; the cut qualified sheets fall through the mesh display holes and are transported out by the bottom conveyor belt; at the same time, the hydraulic system can additionally be utilized for tools upkeep, replacement of devices, and so on. This devices is utilized in the front section of the timber pellet mill offer for sale.

(3) Timber splitter

The wood splitter is an important complementary tools in the wood chip processing sector, as well as there are 2 series of vertical and straight. Its feature is to utilize the hydraulic working concept to split tree stumps, huge tree branches, huge log sectors and hard timber to satisfy the demands of the chipper feeding dimension, or to divide the raw materials right into materials for other functions. The hydraulic cyndrical tube stroke varies in size according to the actual use the consumer. The nominal stress is 30 lots, 35 heaps, and also 50 bunches.

The timber splitter is an important material prep work device in the wood pellet mill plant, paper market, synthetic board market, wood pulp handling as well as various other industries., It has the features of high pressure, time conserving, labor conserving, practical framework, solid and resilient, high outcome, very easy procedure and even more security. This equipment is utilized in the front section of the timber pelletizer equipment.

( 4) Theme crusher

The building formwork crusher is a timber crushing tools developed by our company. It has actually been continuously introduced and also improved for several years. It is currently the 5th generation product. For a long time, our business has actually continuously interacted as well as recognized with customers, and taken in the actual usage experience and troubles of customers, to ensure that the security of the feeding system of the equipment has been constantly boosted; the framework of the crushing cutter head is more reasonable; the discharge is boosted by magnetic separation. This devices is used in the front area of the wood pellet making equipment.

The tools itself can crush steel bars and also iron nails below Φ10 as well as iron sheets and also steel plates listed below δ3mm, eliminating the time-consuming and also laborious difficulty of hands-on option. At the same time, the structure of the crushing system of the design template crusher created by our firm is more stable and also affordable, and the upkeep of the drum chipper and various other equipment is difficult and the difficulty of frequent substitute of accessories. The discharge magnetic separation device embraces a effective permanent magnet to remove iron, which has no power usage, and also the iron elimination can reach more than 90%.

At the same time, the pallet crusher equipment has a small framework as well as is very easy to install, and also the feeding port reaches 300 × 1300mm, which can directly crush waste wood boards, constructing themes, wooden pallets, as well as logs below Φ400.

( 5) Clothes Dryer

The dryer is a kind of drying out tools developed as well as produced by our business for timber handling devices. It is generally utilized for drying sawdust, wood chips as well as various other light particular gravity products. The product is totally blended with the hot air when passing through the pipeline, and is drawn out by the fan. Due to the large contact location in between the product as well as the hot air driven by the follower, the drying out efficiency is considerably raised. Given that the whole drying out process of the air flow dryer is performed in the pipeline, each time the product passes through a bend, it will certainly go into a buffer zone with a larger size, so that the material stays longer and the drying is more adequate. This tools is used in the front section of the wood pellet mill to buy.

Compared to the tumble clothes dryer, the air flow clothes dryer can be constructed in a straight line or zigzag. Given that the drying process is performed in the pipe, even if it is only half the quantity of the tumble dryer, the reliable drying out range is the same as that of the tumble clothes dryer. Greater than twice as long as the dryer. Naturally, the air dryer is not as good as the tumble dryer for products with huge specific gravity (such as rocks) as well as products that are very easy to harden (such as chicken manure, river sand). The price is reduced, the drying out rate is quick, and also the airflow clothes dryer is better than the tumble dryer with a size of greater than 10 meters and one meter.

( 6) Peeling off maker

The debarker is a series of log processing products, mainly made up of a feeding mechanism, a discharging device, a blade roller, a transmission system, a chassis and also various other components. It can additionally complete the peeling off therapy of some icy and dried products. It is commonly made use of for peeling wood such as poplar, cypress, paulownia, eucalyptus, oak, and elm. This equipment is used in the front section of the wood pellet mill up for sale.

The peeling equipment breaks the shortcomings of the conventional drum-type timber peeling machine, which has to be stopped for discharging as well as feeding. The veneer outlet as well as the timber electrical outlet are separated to understand continual job, and the entire process from feeding → peeling → wood output → re-feeding → re-peeling → timber result is continuous, and also the circulation procedure is realized. About different timber types, the peeling impact can be adjusted, and also the wood can be peeled off on the machine for different lengths, bends, as well as moisture. The single-machine trough peeling off equipment can peel 35-50 tons of logs a day, which significantly conserves workforce.

Features of timber peeling equipment:

① Using an open silo, which can be fed from one end as well as released from the other end, conquers the imperfections of the existing drum peeling off machine for feeding, discharging, and segmented work, as well as has high job performance.

② As a result of the effect of the teeth on the timber segment, the timber section not just makes a circular movement in the housing, but likewise rotates around itself, so the peeling off effectiveness is high, as well as the tree varieties that are difficult to peel off such as eucalyptus poplar have a better peeling rate

③ The peeling maker has solid adaptability to timber, and can peel off wood segments of various tree species, diameters, lengths as well as forms. Since the timber segments do rotating movement and also uneven pounding, the scooped part of the curved timber sector can additionally be really comparable to the peeling teeth. Great touch. Consequently, the stripping rate for bent logs is a lot higher than various other drum kinds.

④ Since the big case is taken care of, so the power usage is reduced, the failing price is low, the upkeep workload is little, and the resonance and sound are a lot lower than that of the drum peeling equipment. Easy to mount as well as utilize.

( 7) Belt conveyor

Compared with regular belt conveyors, belt conveyors are preferable for communicating loosened and also light-weight materials, such as timber chips, shavings, grain, etc. This tool is used to link various other equipment and timber pellet mill up for sale.

Compared with the framework belt sharing, the trough communicating has enough depth of the trough, and the light details gravity product can be conveyed faster, as well as it is not ideal for spilling.

At the same time, the feeding trough of the trough belt conveyor can be personalized according to customer needs such as depth, length, width as well as other technological demands, as well as can additionally be completely enclosed to lower dirt pollution during devices procedure.

( 8) Bucket elevator

Pail elevators are generally targeted at the upright conveying of granular materials as well as powdered products. Compared to belt conveyors, because of the vertical communicating method, they have extra benefits than belt conveyors in terms of sharing height as well as floor area.

Our company generally generates three sorts of pail lifts: 160, 250, and also 350. We can personalize various heights (up and down 3 meters), products (carbon steel, stainless steel), transmission approaches (chains, tapes) as well as hoppers according to client needs. Product (plastic, carbon steel, stainless steel). This device is made use of to connect various other tools and also the timber pellet mill up for sale.

For more: Richi Machinery

profile/1956richimachinery.jpg

RichiMachine

1-48T/H Hen Pellet Making Machine For Pet

~5.5 mins read

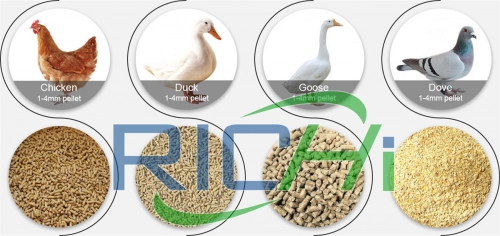

1. RICHI hen pellet making device up for sale

RICHI 1-48T/H high quality chicken pellet making maker for animal hen livestock steed goat duck pet cow prawn pig production, embraces ring die pelletizing devices. The equipment includes power device, transmission, transmission shaft, die plate, pressing roller, feed hopper, cutter and also discharge hopper. The ring die equipped with RICHI poultry pellet making machine is processed according to the data obtained from a large number of experiments on various raw materials, and the effect will be the best for basic raw materials.

Related post:Chicken Feed Making Machine

2. poultry pellet making device uses:

( 1) Feed pelleting

Suitable for feed mills of all dimensions, little output chicken feed pellet making machine appropriates for specialist houses in country farming and also small farms and also poultry farms.

( 2) Unrefined fiber granulation

chicken feed pellet making equipment can also be utilized for granulation of timber chips, rice husks, cotton stalks, cottonseed husks, weeds as well as other plant straws, house trash, manufacturing facility waste, as well as products with low adhesion as well as difficult to create.

Related post:poultry feed pellet machine

3. Difference between the moving plate as well as the moving roller

The chicken feed pellet making equipment created and manufactured by Richi Machinery comes from the ring die pellet device. It implies that the main shaft drives the roller to rotate, and also the ring die does not move. Generally talking, the moving disc kind ring die pellet maker is made use of for small pellet production, and the ring die pellet machine is utilized for larger-scale pellet manufacturing. RICHI feed pellet maker takes on ring die layout, basic framework as well as convenient operation, appropriate for the production of feed pellets of various ranges.

Related post:chicken feed plant

4. Benefits of chicken feed pellet making equipment elements

( 1) Electric control closet: The electrical box remains in the form of plastic spraying, as well as the stamina as well as durability are improved, as well as the covering will not break. Built-in security electronic control system, fully compliant with CE conventional os.

( 2) Gear box: The transmission is made of high-quality cast iron product, with low noise and also great shock absorption. The built-in gear turns, which has high rotation effectiveness as well as lengthy service life compared to the traditional belt equipment.

( 3) Upper box: Integrated die plate and also pressing roller, high-quality alloy steel is utilized to improve the service life. Different die plate designs are suitable for different products to guarantee the important impact.

Related post:3-5T/H Poultry Feed Mill in Malaysia

5. What are the advantages of chicken feed pellet making maker?

What are the advantages of a hen pellet making equipment? Richi Equipment's feed pellet device creates heat and also high pressure during the pressing procedure, the feed has a strong paste aroma, and the feed texture is hard, which adapts the attributes of gnawing animals of chicken, chickens, pigs, cattle and lamb, and also enhances the palatability of the feed. Easy to eat, the nutrient absorption conversion price is enhanced by 300%, safe and also sterilized, the quantity of the straw is doubled after pelleting, which is convenient for long-term storage space and transport.

( 1) Straightforward structure, broad applicability, little impact and also low noise.

( 2) Powdered feed and also turf powder can be granulated without (or a little) liquid enhancement. Therefore, the moisture web content of pelleted feed is basically the dampness content of the material before pelleting, which is more conducive to storage.

( 3) The pellets produced by this poultry pellet making equipment have high solidity, smooth surface as well as enough interior curing, which can improve the food digestion as well as absorption of nutrients, as well as can kill basic pathogenic microbes and bloodsuckers. It appropriates for increasing rabbits, fish, ducks as well as laboratory animals., which is more cost-effective than mixed powder feed.

( 4) This SZLH chicken pellet making maker model is outfitted with 1.5-12mm size mold and mildews, which appropriate for granulation of different products as well as achieve the best result.

( 5) Adjust to different materials to make certain the important impact. Compression molding of timber chips, corn stalks, and so on needs a great deal of stress. In the same kind of chicken feed pellet making device, the roller component is the main part of the entire equipment, as well as the top quality alloy steel is utilized to enhance the life span of the roller.

6. The most significant advantages of feeding livestock as well as hen pellets:

( 1 )It is beneficial to the digestion as well as absorption of the stomach tract of poultry livestock. The pellet feed with great palatability makes the starch in the blended powder gelatinize throughout journalism procedure, to make sure that the pressed pellet feed from the chicken feed pellet making machine has a certain scent, which raises the palatability of the pellet feed, as well as can boost the hunger of hen livestock and make hen animals pleased. Food loves to consume, according to the decision, feeding pellet feed animals can enhance feed intake by 10%-15%.

( 2 )It can properly prevent the out of balance nourishment of animals and also hen due to fussy consuming. When feeding livestock on a daily basis, dog breeders often stress over the selection of concentrated feed in the blended powder for hen animals, and also pellet feed from the chicken feed pellet making device makes all sort of feed resources fully mixed as well as pushed into form, as well as poultry can not be choosy eaters, which can make chicken nutritionally well balanced, it additionally saves feed for farmers and also lowers reproducing costs.

( 3) Boost the digestibility of feed. poultry and also animals chewing pellet feed for a long period of time can advertise the secretion of amylase in the mouth, so that the feed in the mouth of the animals as well as chicken can be fully blended with saliva, promote the peristalsis of the intestines, and also substantially boost the digestibility of nutrients in the feed. On top of that, during the pressing process of chicken feed pellet making maker, through the extensive action of short-term high temperature and also high pressure, not only starch gelatinization and also protein organization in the feed are made, however likewise the activity of enzymes is boosted, so that the beans and also some grains consisted of in the feed are boosted. Inactivation important that restrain the food digestion and also use of nutrients, enhance the digestibility of the feed.

( 4) Sanitation and disinfection, reduce illness. Throughout the pressing process of chicken feed pellet making equipment, the short-term heat as high as 70 ℃ -100 ℃ can kill a part of parasite eggs and also pathogenic bacteria, which can considerably reduce the condition of rabbits. Practice has confirmed that diarrheal illness, stomatitis and also pica in poultry and also animals fed pelleted feed are significantly decreased.

For details please contact: Richi Machinery

WhatsApp:86 138 3838 9622

Email:[email protected]

Advertisement

Link socials

Matches

Loading...