RichiMachine

IT Specialist : IT Specialist : RICHI Machinery Is A Industrial Group Mainly Specialized In The Feed Pellet Machinery , And Also Covers Some Other Strategic Businesses Such As Biomass Pellet Energy Machinery, Organic Fertilizer Pellet Machinery, Parts And Components And So On. RICHI Machinery Has Covered More Than 109 Countries And Regions Around The World From 1995, Products Are Exported To The Middle East, South America, Africa, Southeast Asia And High-end Markets Such As Europe And The United States.

Wants to meet Just Friends

Articles

61

Followers

7

profile/1956richimachinery.jpg

RichiMachine

WhatIsaFishFeedPelletMaker?

~3.3 mins read

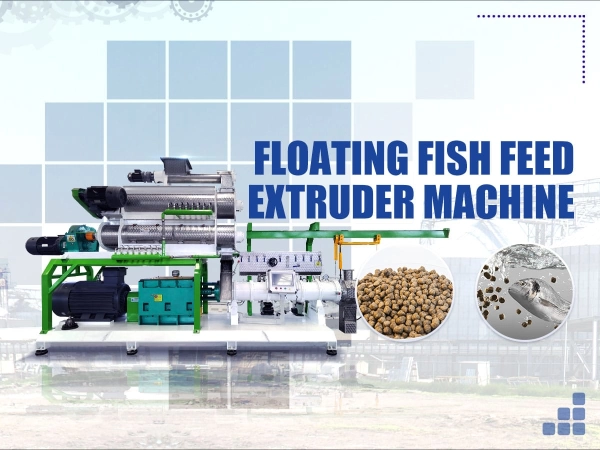

A fish feed pellet equipment is an important tool for the aquaculture sector. It is a device that is particularly designed to create fish feed pellets that are made use of to feed different species of fish, including tilapia, catfish, carp, and also salmon. The device is developed to take basic materials, such as corn, soybean, wheat, and also other grains, and process them right into pellets that are quickly digestible by fish.

Related post: fish feed extruder

Fish feed pellet devices can be found in different sizes and also capabilities, depending upon the demands of the users. The capacity of the equipment is usually gauged in terms of outcome per hr or day. The outcome of a fish feed pellet device can vary from a few hundred kilos per hour to a number of lots per day. The equipment is powered by power, diesel, or fuel, depending on the individual's preference.

The process of making fish feed pellets involves numerous stages. The first stage is the grinding of the raw materials into a fine powder. This is done using a hammer mill or a crusher.

The powder is after that combined with various other ingredients, such as vitamins, minerals, and also fishmeal, to develop a balanced diet regimen for the fish. The next phase is the pelleting process, where the mix is fed right into the fish feed pellet machine. The maker compresses the blend into little pellets that are of a uniform shapes and size. The pellets are after that dried and also cooled to get rid of excess moisture before being packaged for storage or sale.

Fish feed pellet equipments are developed to be straightforward and simple to run. They include a control board that enables the customer to readjust various parameters, such as the rate of the maker, the size and shape of the pellets, as well as the temperature and also wetness material of the pellets. The maker is also made to be very easy to clean and preserve, with compatible components that can be replaced if they become worn or harmed.

Related post: fish feed pelleting machine price

Among the greatest advantages of using a fish feed pellet equipment is that it enables fish farmers to generate premium feed pellets that are customized to the certain needs of their fish. This is necessary since various species of fish have various nutritional needs, as well as feeding them with the incorrect diet can result in illness and even death. By utilizing a fish feed pellet machine, farmers can control the structure and also quality of their fish feed, making sure that their fish are healthy and also well-nourished.

One more benefit of using a fish feed pellet device is that it can assist to decrease waste and improve efficiency. Standard methods of feeding fish, such as hand-feeding or using automatic feeders, can lead to a lot of waste and leftover food. This not just wastes beneficial sources yet can also lead to water pollution and also ecological troubles. By utilizing a fish feed pellet equipment, farmers can produce pellets that are of a consistent size and shape, which decreases waste and guarantees that all the feed is taken in by the fish. linked here

Along with being made use of in the aquaculture sector, fish feed pellet makers can additionally be used in other markets, such as the pet food industry. They can be made use of to generate high-quality dog food, feline food, and various other pet foods. This is due to the fact that the process of making pet food is similar to that of making fish feed pellets, as well as the components utilized are commonly the exact same.

In conclusion, a fish feed pellet equipment is an crucial piece of equipment for the aquaculture sector. It is a device that is developed to generate high-quality fish feed pellets that are customized to the particular needs of various species of fish. The machine is easy to run and also maintain, and also it can help to lower waste and also improve effectiveness in fish farming operations. By utilizing a fish feed pellet maker, fish farmers can ensure that their fish are healthy and balanced and well-nourished, as well as they can add to the sustainable growth of the tank farming industry.

For details please contact: pelleting machine

WhatsApp:86 138 3838 9622

Email:[email protected]

profile/1956richimachinery.jpg

RichiMachine

Wholesale 1-40t/ H Chicken Feed Pellet Maker

~4.9 mins read

The feed pellets generated by the RICHI wholesale 1-40t/ h ce iso factory supply chicken feed pellet device with much less expense, have high firmness, smooth surface as well as internal treating, which can enhance the digestion and absorption of nutrients. The pellet formation procedure can denature the pancreatic enzyme resistance consider grains and also beans, reduce the unfavorable results on digestion, eliminate numerous bloodsucker eggs as well as other pathogenic bacteria, and also reduce various worms and also digestive system diseases.

Related post: chicken feed maker machine

Compared with combined powder feed, higher financial advantages can be gotten. Heat and also high pressure are created throughout journalism procedure, the feed has a solid paste aroma, as well as the feed appearance is hard, which remains in line with the characteristics of poultries, ducks, poultry, pigs, cattle, and also lamb. The nutrient absorption conversion price is enhanced by 300%, non-toxic and sterile, as well as the volume of the straw is doubled after pelleting by poultry feed pellet making equipment, which is convenient for long-term storage as well as transportation.

1. What are the benefits of the chicken feed pellet equipment?

( 1) The chicken feed pellet making maker has affordable layout, straightforward operation, no sound;

( 2) Tiny maker with high result, low power consumption, dry in and also dry out;

( 3) High creating rate, high solidity; smooth surface; convenient for transport as well as storage space;

( 4) Various kinds of grinding discs are suitable for granulation of different products;

( 5) The chicken feed pellet maker apply various materials to make sure the pressing effect;

( 6) Basic operation and also upkeep, safe and reliable;

( 7) Solid versatility to the office;

( 8) Solid framework, stunning look as well as long life span.

2. Why acquire RICHI fowl feed pellet making equipment?

( 1) Features of 1-10T/ H chicken feed pellet machine

Compact structure and gorgeous appearance;

High outcome, reduced power usage, easy to use as well as reliable performance;

The pressure rollers are equally organized, the procedure is secure, and the pressing area is increased to boost the manufacturing effectiveness;

The space in between the fowl feed pellet making maker molds can differ from dimension to dimension, appropriate for different products to make certain the pressing impact;

There is an monitoring door, which can be checked at any time for very easy maintenance and repair.

( 2) Attributes of 11-20T/ H chicken feed pellet equipment

Compact structure, lovely look, high output and low power intake;

The chicken feed pellet equipment stress rollers are equally set up, and the operation is secure;

The gap in between the molds can vary from dimension to dimension, suitable for various materials to make sure the important impact;

There is an monitoring door, which can be checked at any moment for easy repair and maintenance.

( 3) Attributes of 21-40T/ H chicken feed pellet machine

Scientific and affordable architectural design, straightforward, small impact, reduced noise;

Dry in and also dry, easy to make materials, high outcome and low energy usage;

High pellet creating price, high solidity, smooth surface area, convenient for storage space as well as transport;

chicken feed pellet device adapts to different materials to guarantee the pressing impact;

The body is cast all at once, the structure is firm and also the appearance is gorgeous, and also the life span is long.

Related post: poultry feed plant project

4. Customize the chicken feed pellet maker plan for you:

Richi Machinery full collection of chicken feed pellet equipment, feed processing as well as production equipment independently established as well as developed by our business, usual matching equipment includes: crushing devices, feeding devices, drying out tools, pelletizing devices and air conditioning and also product packaging devices, and so on; the outcome can be various according to customers, Tailor-made for different breeding animals as well as various requirements to totally meet the demands of clients.

Series of processing resources: corn, soybean dish, bran, rice husk, corn stalk, peanut husk, rice straw and various other common feed formula resources.

Handling modern technology: crushing-- feeding-- drying out-- feeding-- granulating-- air conditioning-- packaging.

Resources of various sizes are grated by a pulverizer right into a ideal size for granulation, get in the silo, as well as get in the poultry feed pellet making equipment via a screw communicating at a uniform rate. The pellets pushed by the chicken feed pellet machine enter the air conditioning and testing maker. Can be packaged and also marketed. Various assembly line can be offered according to consumer result requirements; suitable for big, medium as well as little feed producers, big ranches, etc.

In the production procedure of the chicken feed pellet device, the most crucial element is the die plate, and the option of the aperture dimension of the die plate plays a really essential role in the reproduction of farmers.

Farmers can pick matching mold and mildew plates with different apertures according to different pets, as well as can recognize private one-to-one mold plate personalization. The original plan can improve the life and performance of the chicken feed pellet device!

Related post: Chicken Feed Factory

5. Richi Equipment chicken feed pellet maker Laboratory

Richi Pellet Equipment gives solutions - to aid consumers detect manufacturing pellets, recognize client customized production, and also guarantee optimal consumer advantages.

According to the marketplace circumstance, the joint research laboratory will actively react to pertinent nationwide policies on brand-new energy, track foreign sophisticated modern technologies, construct brand-new laboratory brand-new power core technologies, establish first-rate poultry feed pellet making machine, and also advertise the adjustment and optimization of the nationwide power framework. The freshly acquired ingrained calorimeter, stamina tester, pulverization level determining instrument and also various other instruments in the laboratory provide us with a extra targeted instructions for adjusting as well as looking into the chicken feed pellet device, which can recognize real-time testing of after-sales production pellets, as well as make use of innovative instruments to find customers. Fulfillment of manufacturing pellets plays an important role in improving machines.

For details please contact: Richi Machinery

home

WhatsApp:86 138 3838 9622

Email:[email protected]

Advertisement

Link socials

Matches

Loading...