Kuamo

Others

Wants to meet Engineers : Very Skillful In There Line Of Duty....

Articles

145

Followers

21

profile/9093IMG-20200801-WA0028.jpg

Kuamo

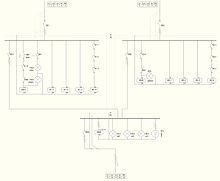

How The Automatic Changeover

~7.4 mins read

A transfer switch is an electrical switch that switches a load between two sources. Some transfer switches are manual, in that an operator effects the transfer by throwing a switch, while others are automatic and trigger when they sense one of the sources has lost or gained power.

An Automatic Transfer Switch (ATS) is often installed where a backup generator is located, so that the generator may provide temporary electrical power if the utility source fails.

Operation of a transfer switchEdit

As well as transferring the load to the backup generator, an ATS may also command the backup generator to start, based on the voltage monitored on the primary supply. The transfer switch isolates the backup generator from the electric utility when the generator is on and providing temporary power. The control capability of a transfer switch may be manual only, or a combination of automatic and manual. The switch transition mode (see below) of a transfer switch may be Open Transition (OT) (the usual type), or Closed Transition (CT)).

For example, in a home equipped with a backup generator and an ATS, when an electric utility outage occurs, the ATS will tell the backup generator to start. Once the ATS sees that the generator is ready to provide electric power, the ATS breaks the home's connection to the electric utility and connects the generator to the home's main electrical panel. The generator supplies power to the home's electric load, but is not connected to the electric utility lines. It is necessary to isolate the generator from the distribution system to protect the generator from overload in powering loads in the house and for safety, as utility workers expect the lines to be dead.

When utility power returns for a minimum time, the transfer switch will transfer the house back to utility power and command the generator to turn off, after another specified amount of "cool down" time with no load on the generator.

A transfer switch can be set up to provide power only to critical circuits or to entire electrical (sub)panels. Some transfer switches allow for load shedding or prioritization of optional circuits, such as heating and cooling equipment. More complex emergency switchgear used in large backup generator installations permits soft loading, allowing load to be smoothly transferred from the utility to the synchronized generators, and back; such installations are useful for reducing peak load demand from a utility.

TypesEdit

Open transitionEdit

An open transition transfer switch is also called a break-before-make transfer switch. A break-before-make transfer switch breaks contact with one source of power before it makes contact with another. It prevents backfeeding from an emergency generator back into the utility line, for example.[1] One example is an open transition automatic transfer switch (ATS). During the split second of the power transfer the flow of electricity is interrupted. Another example is a manual three position switch or circuit breaker, with utility power on one side, the generator on the other, and "off" in the middle, which requires the user to switch through the full disconnect "off" position before making the next connection.

Closed transitionEdit

A closed transition transfer switch (CTTS) is also called a make-before-break transfer switch.

A typical emergency system uses open transition, so there is an inherent momentary interruption of power to the load when it is transferred from one available source to another (keeping in mind that the transfer may be occurring for reasons other than a total loss of power). In most cases this outage is inconsequential, particularly if it is less than 1/6 of a second.

There are some loads, however, that are affected by even the slightest loss of power. There are also operational conditions where it may be desirable to transfer loads with zero interruption of power when conditions permit. For these applications, closed transition transfer switches can be provided. The switch will operate in a make-before-break mode provided both sources are acceptable and synchronized. Typical parameters determining synchronization are: voltage difference less than 5%, frequency difference less than 0.2 Hz, and maximum phase angle between the sources of 5 degrees. This means the engine driving the generator supplying one of the sources generally must be controlled by an isochronous governor.

It is generally required that the closed transition, or overlap time, be less than 100 milliseconds. If either source is not present or not acceptable (such as when normal power fails) the switch must operate in a break-before-make mode (standard open transition operation) to ensure no backfeeding occurs.

Closed transition transfer makes code-mandated monthly testing less objectionable because it eliminates the interruption to critical loads which occurs during traditional open transition transfer.

With closed transition transfer, the on-site engine generator set is momentarily connected in parallel with the utility source. This requires getting approval from the local utility company.

Typical load switching applications for which closed transition transfer is desirable include data processing and electronic loads, certain motor and transformer loads, load curtailment systems, or anywhere load interruptions of even the shortest duration are objectionable. A CTTS is not a substitute for a UPS (uninterruptible power supply); a UPS has a built-in stored energy that provides power for a prescribed period of time in the event of a power failure. A CTTS by itself simply assures there will be no momentary loss of power when the load is transferred from one live power source to another.[2]

Soft loadingEdit

A soft-loading transfer switch (SLTS) makes use of a CTTS, and is commonly used to synchronize and operate onsite generation in parallel with utility power, and to transfer loads between the two sources while minimizing voltage or frequency transients.[3][4][5]

Static transfer switch (STS)Edit

A static transfer switch uses power semiconductors such as Silicon-controlled rectifiers (SCRs) to transfer a load between two sources. Because there are no mechanical moving parts, the transfer can be completed rapidly, perhaps within a quarter-cycle of the power frequency. Static transfer switches can be used where reliable and independent sources of power are available, and it is necessary to protect the load from even a few power frequency cycles interruption time, or from any surges or sags in the prime power source.[6] [7]

profile/9093IMG-20200801-WA0028.jpg

Kuamo

The Book For Every ELECTRICAL Engineer

~6.0 mins read

*TABLE OF CONTENT*

*Chapter 1.*

*AUTOMATION*

*1.1* Home Automation

*1.2* . Automatic Changeover Switch (ATS)

*1.2.1* The 7 Different kinds of Automatic Changeovers that we will learn how to build are.

*1.2.2* Single Phase Automatic Changeover with one contactor, one timer and an alarm.

*1.2.2.1* Step by Step Procedures of building Single Phase Automatic Changeover with one contactor, one timer and an alarm.

*1.2.3* . Single Phase Automatic Changeover with two contactors and one 8 - pin relay.

*1.2.3.1* Step by Step procedures of building Single Phase Automatic Changeover with two contactors, and one 8 - pin relay.

*1.2.4.* 3 - Phase Automatic Changeover with two contactors and one 8 - pin relay

*1.2.4.1* . Step by Step procedures of building a 3 - Phase Automatic Changeover with two contactors and one 8 - pin relay.

*1.2.5* . Automatic Changeover that can switch OFF the generator.

*1.2.5.1* . Step by Step procedures of building Automatic Changeover that can switch OFF the generator.

*1.2.6* . Automatic Changeover that can switch OFF and Switch ON the generator.

*1.2.6.1* . Step by Step procedures of building Automatic Changeover that can switch OFF and Switch ON the generator

*1.2.7* Automatic Changeover that can delay before switching to another power supply.

*1.2.7.1* Step by Step procedures of building Automatic Changeover that can delay before switching to another power supply.

*1.2.8* . Automatic Changeover that can switch between 3 different power supplies.

*1.2.8.1* . Step by Step procedures of building Automatic Changeover that can switch between 3 different power supplies.

*Chapter 2.*

*CCTV CAMERA INSTALLATION*.

*2.1* Components of CCTV System

*2.1.1* . Camera

*2.1.2* Monitor

*2.1.3* Digital Video Recorder ( DVR )

*2.1.4* VGA Cable ( Video Graphic Array )

*2.1.5* . BNC Connector ( Bayonet But Connector )

*2.1.6* . Coaxial Cable

*2.1.7* . CCTV Power Supply.

*2.1.8* . Hard Drive

*2.1.9* . Step by Step procedures of CCTV camera System Installation.

*Chapter 3*

*SOLAR ENERGY*

*3.1* . Solar Panel

*3.2* . Charge Controller

*3.3* . Battery ( Picture of battery )

*3.4* Inverter

*3.5* . Connections of Solar Panels.

*3.5.1* . Connecting Your Solar Panel in Series.

*3.5.2* . Connecting your Solar Panel in Parallel.

*3.5.3* . Connecting your Solar Panel in Series and in Parallel.

*3.6* . Connection of Batteries.

*3.6.1* . Connecting Your Batteries in Series

*3.6.2* . Connecting your Batteries in Parallel

*3.6.3* . Connecting your Batteries in Series and in Parallel

*3.7* . Stand Alone Solar PV System.

*3.7.1* . Types of Stand Alone PV System.

*3.7.2* . Stand Alone ( PV ) system with only DC Load.

*3.7.3* . Stand Alone ( PV ) / Panel System with DC Load and Electronic Control Circuit / Charge Controller.

*3.7.5* . Stand Alone Solar ( PV ) System with AC / DC load, Electronic Control Circuit and battery.

*3.8* . Calculations of sizing and rating of Solar Power Systems.

*3.8.1* . How to Calculate Solar Battery Backup Time

*3.9* Using the Solar Energy in raining days.

*Chapter 4* .

*DESIGN AND BUILDING OF SOLAR GENERATOR KITS.*

*4.1* . Connection Steps of Solar Generator Kit.

*chapter 5.*

*CONNECTION OF PANEL COMPONENTS*

*5.1* . Contactor

*5.1.1* . Things that made up a contactor.

*5.1.2* . How contactors work

*5.1.3* . Connection Procedures of contactors

*5.2* . Timer

*5.2.1* . Connection Procedures of Timer

*5.3* . Pin relay

*5.3.1* . Connection Procedures of Pin relay

*5.4* . Voltage Monitor

*Chapter 6.*

*INDUSTRIAL PANELS*

*6.1* . Starter Panels

*6.1.1* . Direct Online Starter Panel ( DOL )

*6.1.1.1* . Single Phase DOL Starter Panel

*6.1.1.2* . Procedures to build a Single Phase DOL Panel

*6.1.1.3* . 3 Phase DOL Starter Panel.

*6.1.1.4* . Procedures to build a 3 Phase DOL Panel

*6.1.2* . Forward and Reverse Starter Panel

*6.1.2.1* Procedures to build a Forward and Reverse panel

*6.1.3* . Star Delta Starter Panel.

*6.1.3.1* . Procedures to build a Star Delta Starter Panel.

*6.2* . Multi Purpose Panel

*6.2.1* . Step by Step procedures of connecting Multi Purpose Panel.

*Chapter 7*

*FIRE ALARM SYSTEM*

*7.1* . Types of Fire Alarm Detectors

*7.1.1* . Heat Detectors

*7.1.2* . Smoke Detectors

*7.1.2.1* . Ionization Smoke Detectors

*7.1.2.2* . Photoelectric Smoke Detectors

*7.1.3* . Carbon Monoxide Fire Detectors

*7.1.4* . Multi Sensor Detector

*7.1.5* . Manual Call Point

*7.2* . Different types of Fire Alarm System

*7.2.1* . Conventional Fire Alarm System.

*7.2.2* . Addressable Fire Alarm System

*7.2.3* . Intelligent Fire Alarm System.

*7.2.4* . Wireless Fire Alarm System

*Chapter 8*

*COIL WINDING*

*8.1* Motor Rewinding

*8.1.1* . Components that made up the motor.

*8.1.2* . Stator

*8.1.3* . A mature

*8.1.4* . Coil

*8.1.5* . Step by Step procedures of Motor Rewinding.

*8.2* . Transformer Winding

*8.2.1* . Components needed for Transformer Winding

*8.2.2* . Former

*8.2.3* . Lamination ( E & I Lamination)

*8.2.4* . Coil

*8.2.5.* Lamination Tape

*8.2. 6.* Step by Step procedures of Transformer Winding.

*Chapter 9.*

*CONTROL OF WATER LEVEL IN THE THANK USING FLOAT SWITCH*

*9.1* . Ways of connecting the float switch.

*9.1.1* . Connecting the float switch direct from the power supply to the pumping machine.

*9.1.1.1* . Procedures of connecting the the float switch direct from the power supply to the pumping machine.

*9.1.2* . Connecting the float switch to the pumping machine using a contactor.

*9.1.2.1* . Procedures of connecting the float switch to the pumping machine using a contactor.

*9.1.3* . Connecting the float switch to the pumping machine ( motor ) using a pin relay.

*9.1.3.1* Procedures of connecting the float switch to the pumping machine using a pin relay.

*Chapter 10*

*LED BULB*

*10.1* . LED Driver

*10.2* . Components of LED Bulb

*10.2.1* . LEDs

*10.2.2* . Drivers ( chokes )

*10.2.3* . PCB Plates ( Printed Circuit Board )

*10.2.4* . Housing

*10.2.5* . Procedures to produce LED Bulb

*Chapter 11*

*SIMPLE ALARM SYSTEM*

*11.1* . Procedures of Simple Alarm System Installation

*Chapter 12.*

*HOW TO CHOOSE THE RATING OF COMPONENTS AND SIZE OF WIRES FOR ANY INSTALLATION YOU ARE DOING*

*12.1* . How to choose the rating of components

*12.2* . How to choose the size of wires for any installation

*Chapter 13*

*INVERTER DESIGN*

*13.1* . Building of Inverter

*13.2* . Connection Procedures of Inverter.

Advertisement

Link socials

Matches

Loading...